Airsoft, a growing sport globally, offers enthusiasts the thrill of simulated combat using replicas of real firearms. The small spherical projectiles, commonly known as airsoft BBs, play a crucial role in this sport. But have you ever wondered what airsoft BBs are made of? This article delves into the materials and manufacturing processes behind these tiny yet essential components.

Understanding Airsoft BBs: What Exactly Are They Made From?

Airsoft BBs, typically measuring 6mm in diameter, are the ammunition used in airsoft guns. Unlike real bullets, BBs are non-lethal and designed to be safe for sport usage under controlled conditions. Understanding the materials that make up these BBs is key to appreciating their function and safety features.

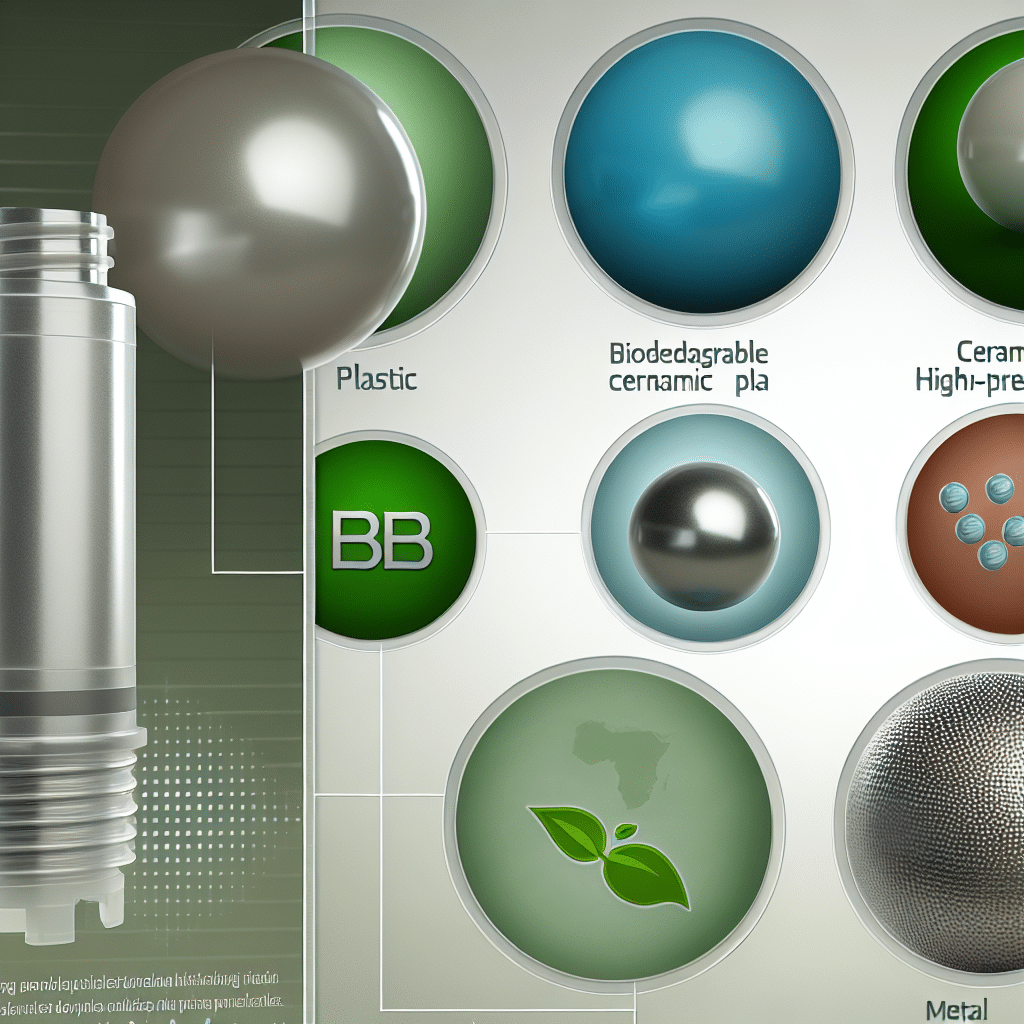

Plastic BBs: The Standard Choice

Most airsoft BBs are made from plastic, specifically Acrylonitrile Butadiene Styrene (ABS) or Polylactic Acid (PLA). ABS plastic is favored for its strength, durability, and relatively low cost. It offers a smooth finish, which is crucial for ensuring the BBs travel accurately through the airsoft gun barrel. PLA is another popular material, especially for biodegradable BBs. As an eco-friendly alternative, PLA is derived from renewable resources such as cornstarch, offering an environmentally conscious choice for players.

Biodegradable BBs: An Eco-friendly Alternative

The increasing concern for the environment has led manufacturers to produce biodegradable BBs. These BBs are made from materials like PLA or a combination of other biodegradable polymers, which break down naturally over time. While biodegradable BBs are slightly more expensive than traditional plastic ones, they offer a sustainable option that reduces environmental impact, particularly in outdoor fields.

Ceramic and Metal BBs: For the Advanced Player

Though less common, ceramic and metal BBs exist and are used primarily in specialized scenarios. Ceramic BBs are incredibly hard and offer high precision, making them suitable for target shooting. However, their hardness can cause more wear and tear on airsoft guns. Metal BBs, often made from steel or aluminum, are heavier than plastic or biodegradable BBs. They are typically used for increased impact in airsoft games but are not recommended for use in standard airsoft guns due to their potential to cause damage.

Why Are Different Materials Used in Airsoft BBs?

The choice of material for airsoft BBs impacts their performance, cost, and environmental footprint. Here’s why manufacturers opt for different materials:

Performance

Material composition affects the BB’s weight, hardness, and smoothness, all of which contribute to its overall performance. For example, heavier BBs (like metal ones) can travel further and straighter but require more powerful guns to propel them. Plastic BBs offer a balance of weight and smoothness, ensuring good performance in standard airsoft guns.

Cost

Plastic BBs, particularly those made from ABS, are inexpensive to produce, making them the most common choice among players. Biodegradable BBs, although more costly, attract players who are willing to pay a premium for environmental sustainability. Ceramic and metal BBs, being specialized products, come at a higher price and are usually purchased by advanced players for specific uses.

Environmental Impact

Traditional plastic BBs, if not disposed of properly, can contribute to environmental pollution. Biodegradable BBs address this issue by breaking down over time, reducing the ecological footprint of the sport. As the airsoft community becomes more environmentally conscious, the demand for biodegradable BBs is expected to rise.

How Are Airsoft BBs Manufactured?

The manufacturing process of airsoft BBs involves multiple steps to ensure consistency and quality:

Injection Molding

Plastic BBs are typically produced using injection molding. This process involves melting plastic pellets and injecting the molten plastic into molds shaped like spheres. Once cooled, these spheres form the BBs. This method allows for mass production, ensuring uniform size and shape.

Polishing

After molding, the BBs undergo a polishing process to achieve a smooth surface. Polishing is vital as it reduces friction when the BB travels through the barrel, enhancing accuracy and reducing wear on the airsoft gun.

Quality Control

Quality control is a critical aspect of BB manufacturing. Each batch of BBs is tested for size consistency, weight, and smoothness. Inconsistent BBs can jam in the gun’s barrel or reduce accuracy, affecting gameplay and potentially damaging the equipment.

Conclusion: Choosing the Right BBs for Your Game

So, what are airsoft BBs made of? The answer varies depending on the type and intended use. From sturdy plastic and eco-friendly biodegradable materials to specialized ceramic and metal options, each type of BB offers unique benefits and trade-offs. Understanding the material composition of airsoft BBs allows players to make informed decisions, enhancing their gameplay experience while considering cost and environmental impact.

Whether you are a novice player or an experienced enthusiast, choosing the right BBs can make a significant difference in your airsoft adventures. As technology and environmental awareness evolve, the future of airsoft BBs promises even more innovative and sustainable options.